Our Quality Assurance and Quality Control (QA/QC) department is responsible for overseeing all production stages—from design and development to final assembly and product release. By adhering to international and industrial standards such as ISO 9001 (Quality Management), ASTM (Material and Product Testing Standards), IEEE (Electrical and Electronics Engineering), RoHS (Restriction of Hazardous Substances), and JEDEC (Memory Standards for RAM and SSD), we ensure that every product is manufactured with the highest level of quality and precision.

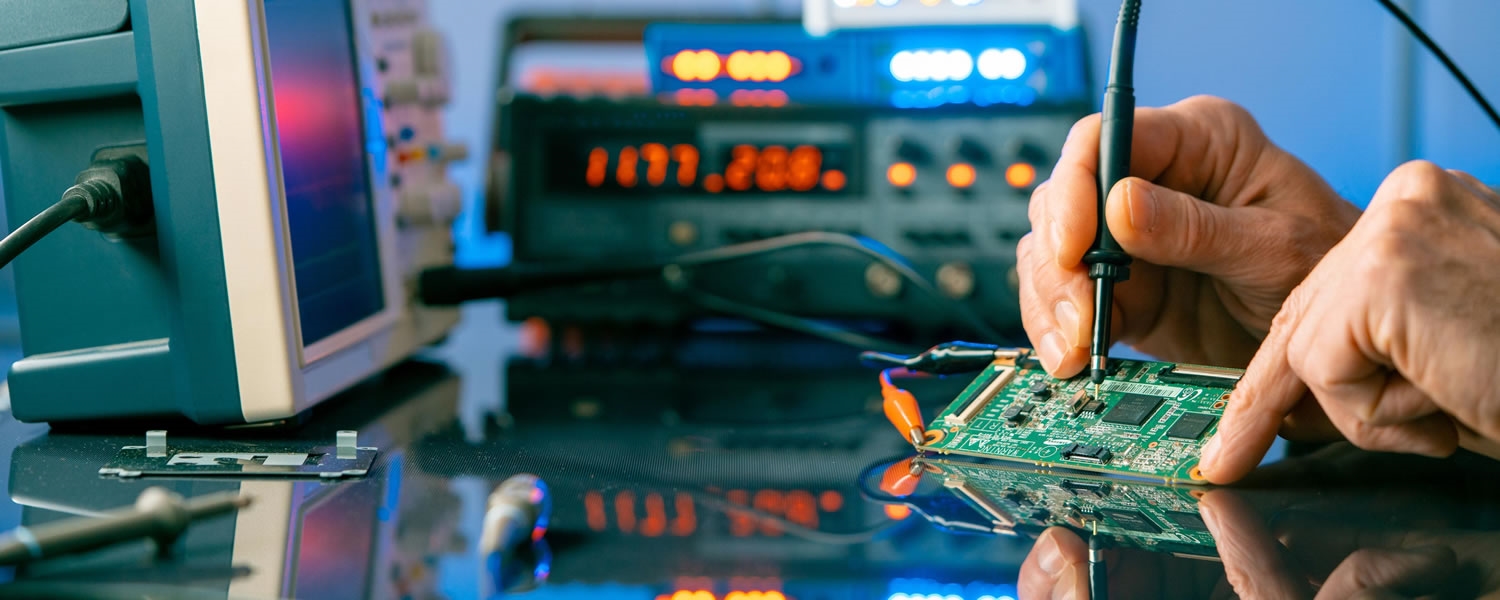

Electronic Circuit Boards (PCBs) are produced with a strict adherence to IPC-A-610 standards for component assembly quality and IPC-6012 for technical performance and testing. These standards guarantee that our circuit boards meet the demanding requirements for IP Camera Systems, Building Automation, and Smart Modules with exceptional reliability. Additionally, rigorous environmental and mechanical testing evaluates product resilience and durability, reducing error rates and enhancing product lifespan.

For Smart Modules and Surveillance Systems, our QA/QC team employs global standards such as KNX, Zigbee, Wi-Fi, and Z-Wave to ensure that every module and system aligns with international protocols and performs optimally within smart home and building automation environments.

In Lithium-Ion Battery manufacturing, standards like IEC 62133, UL 1642 (Lithium-Ion Cell Safety), and UN 38.3 (Battery Transportation Testing) are strictly followed. Our quality control processes include charge/discharge testing, thermal testing, and pressure testing to produce batteries with high performance and safety standards for diverse applications, including smart devices and portable equipment.

For RAM and SSDs, we rely on JEDEC standards and employ Statistical Process Control (SPC) techniques alongside extensive testing for data transfer rates, shock resistance, and stability under various environmental conditions. Given the sensitivity of these products, particularly for intensive applications like data centers and cloud computing, our QA/QC team executes stringent testing and quality control protocols.

The QA/QC department performs Environmental Stress Screening (ESS) and Life Cycle Testing to evaluate product performance across varied environmental conditions, including extreme temperatures, high humidity, and mechanical vibrations.

Through a comprehensive Total Quality Management (TQM) system, advanced Statistical Process Control (SPC), and tools such as Six Sigma, Root Cause Analysis (RCA), Advanced Product Quality Planning (APQP), and Failure Mode and Effects Analysis (FMEA), our QA/QC team not only reduces product failure rates but also drives continuous improvements in manufacturing processes. These efforts increase customer trust and strengthen our products’ competitive edge in both domestic and international markets.